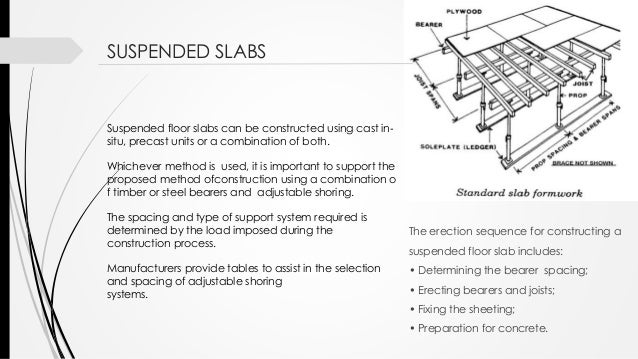

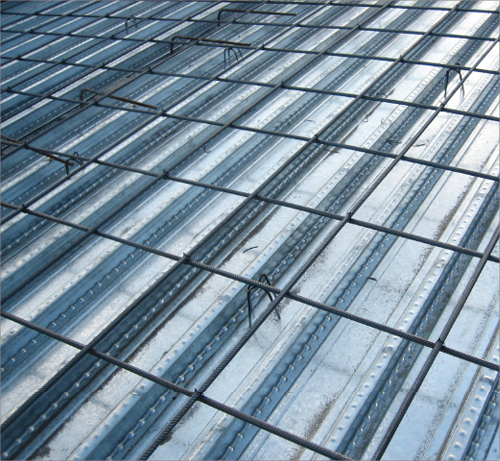

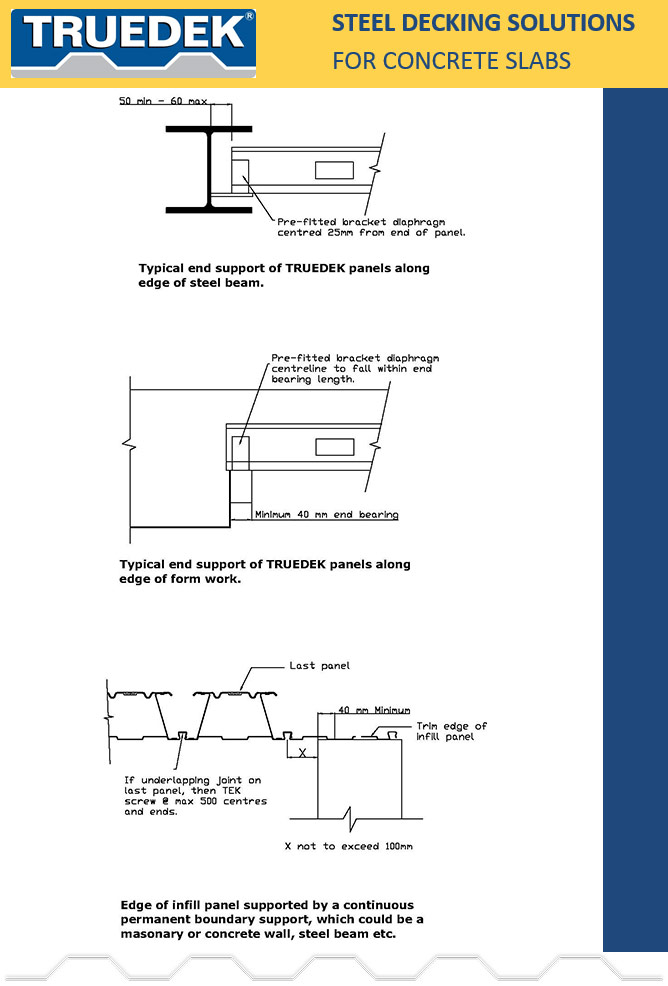

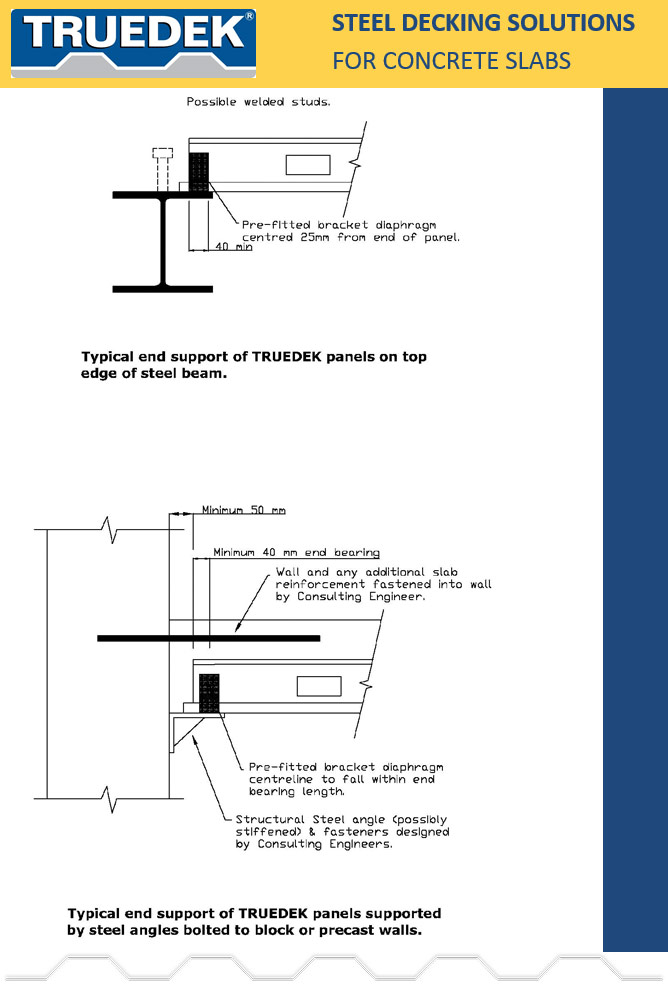

Slab formwork includes formwork panels, stringers, joists, shores, and other supporting materials that enables the concrete to be poured and set above the ground There are a variety of materials used in slab formwork, including plywood, timber, metal, aluminium, and sometimes even plastic components that are used to shape and give strength toTRUEDEK ® is a permanent steel suspended slab formwork system that provides significantly more features and a number of additional benefits compared to existing steel formwork and metal decking systems Installation Download your Installation Guide, including prestart needs, detailing requirements, safety instructions and installation procedures for all configurationsSuspended slabsFor a suspended slab, there are a number of designs to improve the strengthtoweight ratio In all cases the top surface remains flat, and th

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Suspended slab formwork details

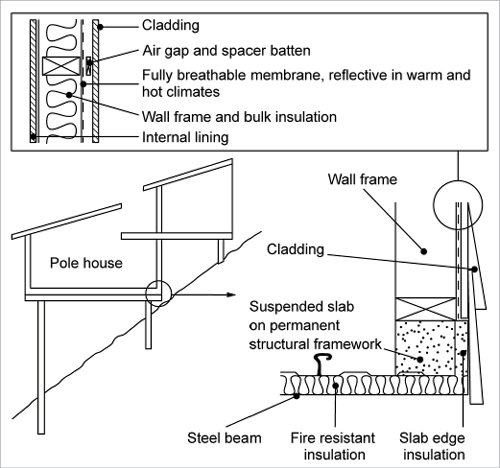

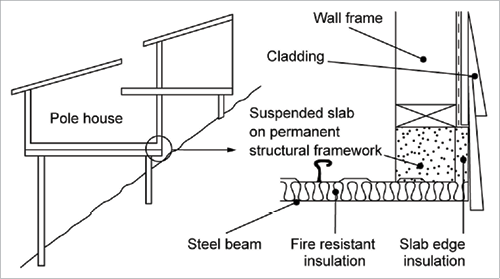

Suspended slab formwork details- The reinforced concrete floor slab is kept free of the perimeter walls The mesh reinforcement in the slab is placed in the top with 1" covers The slab is constructed on well compacted granular fill, crushed stone or marl Figure B10 Alternative Floor Slab Detail The suspended reinforced concrete slab is tied into the external capping beamPractical activity for Illawarra Carpentry Students to complete formwork to suspended slabs beams and columns

Concrete Formwork For Slabs

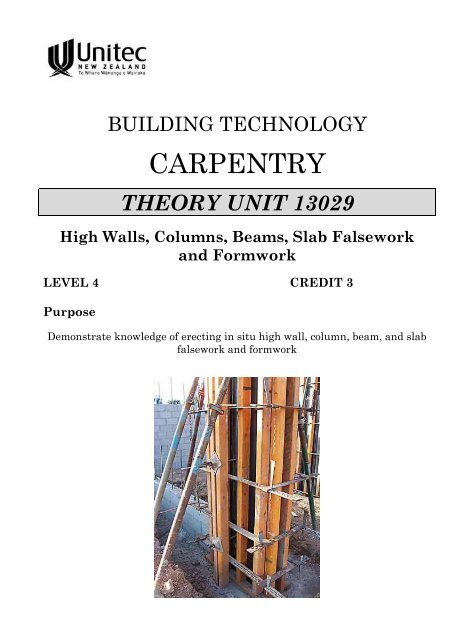

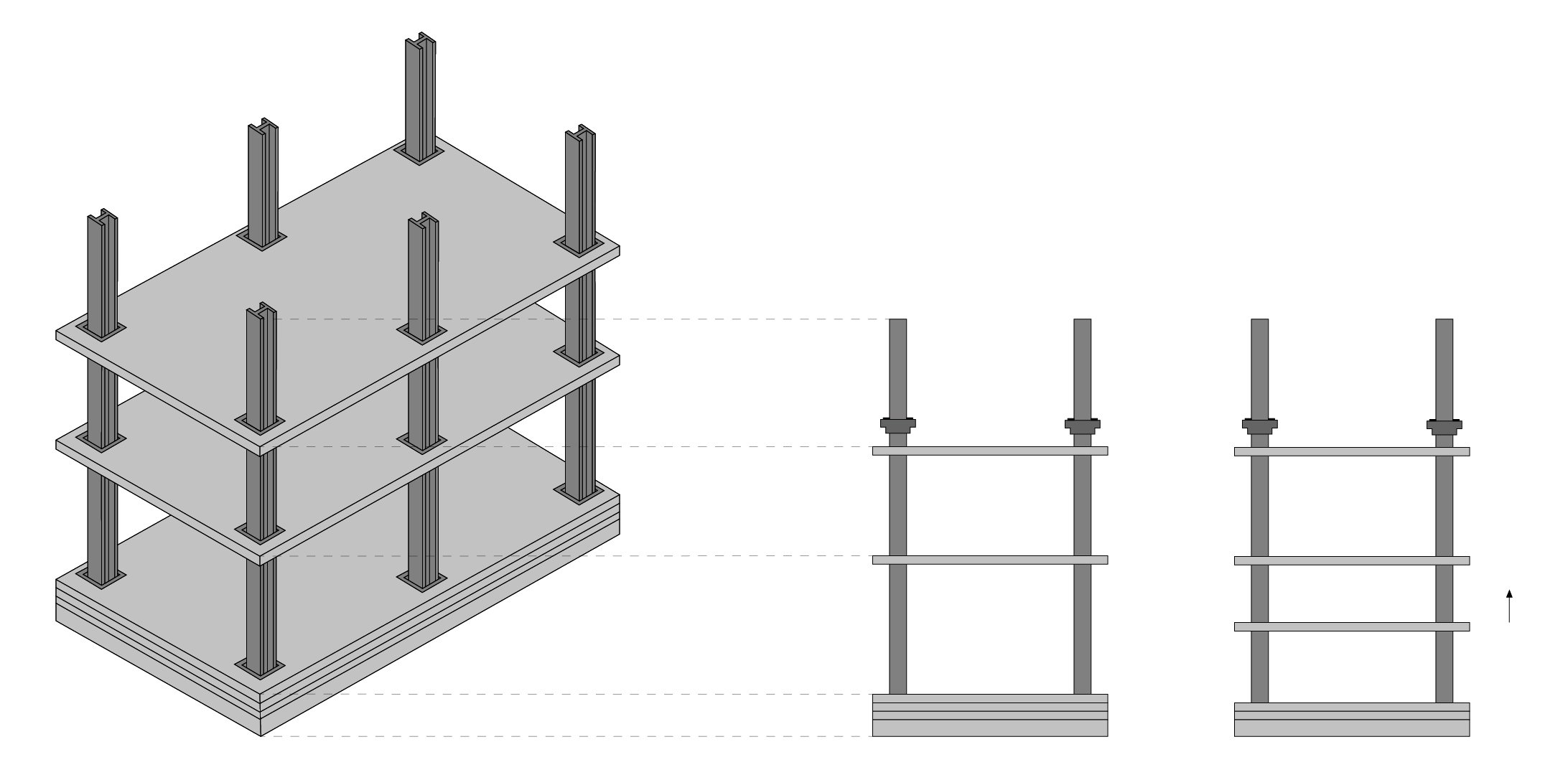

This unit of competency specifies the outcomes required to erect and dismantle formwork to suspended slabs, columns, beams and walls to contain concrete in above ground construction It includes timber, metal or prefabricated formwork of modular or in situ designPrecast suspended slabs are constructed by pouring the slab in a formwork on the ground and then lifting the slab into its suspended position in the structure Formwork is installed on top of the struts and beams Reinforcement is assembled on top of the formwork Concrete is then poured into the29m Hbeam = 17 22 = 39 pieces;

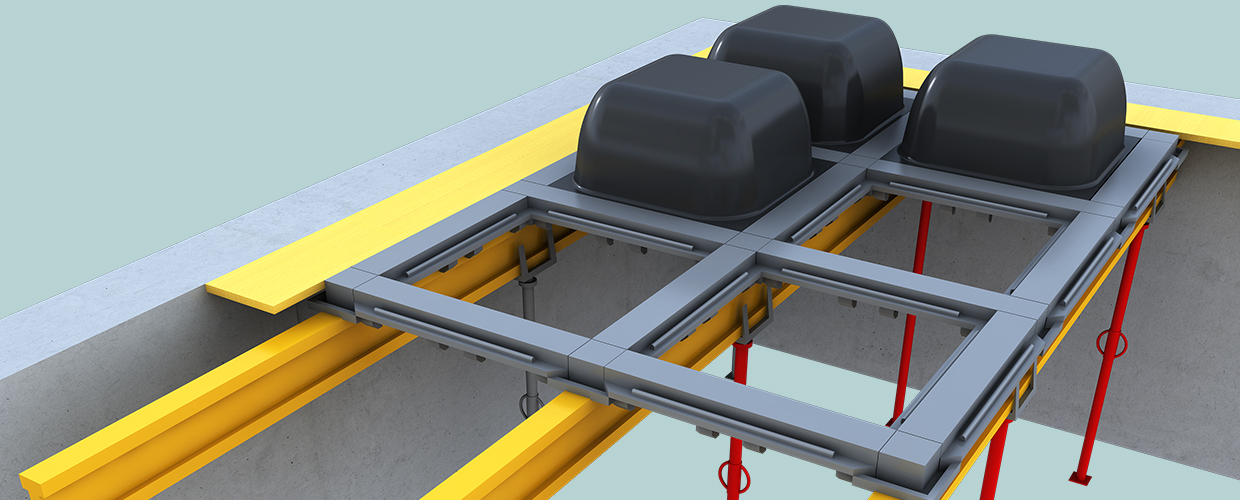

This fasttrack suspended slab system forms a ribbed concrete structure that provides a reduction in weight while maintaining strength and superior insulation levels FormDeck™ is a lightweight form used to create insulated suspended slab construction The EPS profile forms structural concrete T beams integrated with a thinner flat concrete slabThereof, How does a suspended slab work?Quality Slab Formwork Systems manufacturers & exporter buy Safety Suspended Slab Formwork Shifting Trolley With Hydraulic Power from China manufacturer ZNLS ENGINEERING CO, LTD ZNLS ENGINEERING MOST EXCELLENT FORMWORK SOLUTION Contact Details ZNLS ENGINEERING CO, LTD Contact Person sophia liu Send your inquiry directly to us (0

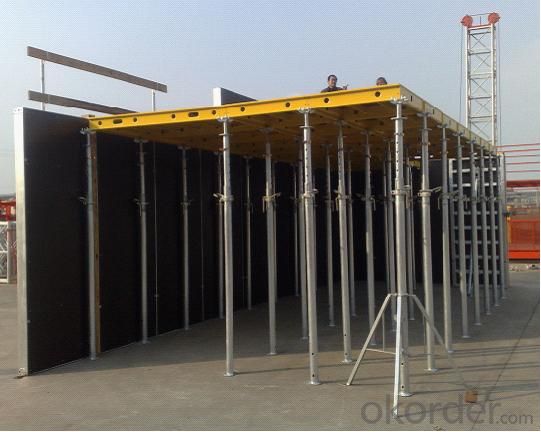

Formwork summary for floor slab;Formwork 21 Work area is cleared and surface prepared for safe erection of formwork for suspended slabs, piers and shutters 22 Formwork is set out to requirements of plans and specifications 23 Formwork is assembled to plans, specifications and class of surface finish, with support system set to correct height level and line 24Dokadek 30 is a beamless, handset formwork system designed as a lightweight steel structure with yellow coated frames faced with timber/plasticcomposite sheeting Dokadek 30 combines the advantages of a panel floor formwork system with those of Dokaflex floorslab formwork

File Slab Formwork Tables Jpg Wikimedia Commons

Concrete Formwork Suspended Slab Personal Protective Equipment Architect

Note that all these materials can be hired because they are very reusable This is one of the advantagesBONDEK® composites slabs can be designed to achieve a fireresistance of up to 240 minutes For fire resistance levels of 90 and 1 minutes, the BONDEK® ribs contribute significantly to the resistance of the slab in fire Composite slabs incorporating BONDEK® can be designed in a number of ways • Using the design tables given in this manualThe formwork is the frame for the concrete slab For measurements, consult the approved building plans to ensure the formwork is setup correctly Following the process of laying the formwork correctly, reduces the likelihood that the concrete slab is compromised Preparation of formwork must also follow established building standards and

Suspended Slab Formwork Cassaform Construction Systems

Concrete Slab Floors Yourhome

BONDEK ® SE DE 2 BONDEK® STRUCTURAL STEEL DECK USER GUIDE USING LYSAGHT® BONDEK® STRUCTURAL STEEL DECK BONDEK® Structural Steel Decking is a highly efficient, versatile and robust formwork, reinforcement and ceiling system for concrete slabs It is a profiled steel sheeting widely acceptedSlab or other structural member after the original forms and (supported or suspended) and its supporting structure used for supporting workers, tools, and materials;This unit of competency specifies the skills and knowledge required to erect and dismantle formwork to suspended slabs, columns, beams and walls to contain concrete in aboveground construction, meeting all relevant requirements of the National Construction Code (NCC), Australian Standards, work health and safety (WHS), and Commonwealth and state or territory legislation

Concrete Formwork For Slabs

Formwork Design Calculation Jobs Ecityworks

A corrugated suspended reinforced concrete slab is made using a combination of steel and concrete Concrete is poured onto a strong steel tray, which gives it added strength for use in building or other construction purposes The tray will have a corrugated design39m Hbeam = 51 = 139 pieces; Designated by Cross Sections, Nominal Dimensions (prior to finishing) After cut length wise, finishing operations reduces actual dimensions 2 x 4 Plank 1 1/2 x 3 1/2 ® 2" by 4" in S4S Lengths are multiples of 2 ft (8, 10, 12, 14, 16,)

Detail Of Reinforced Concrete Slab With Lightweight Concrete Blocks Under Construction Construction Site Slab Construction Rebar Concrete Structure Building Formwork Concrete Floor Beam Structural Bar Dawn Architect Architecture Block

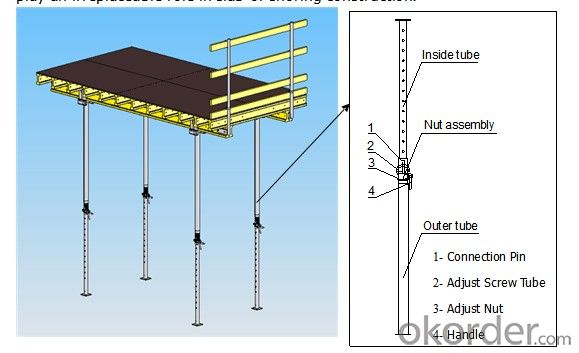

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

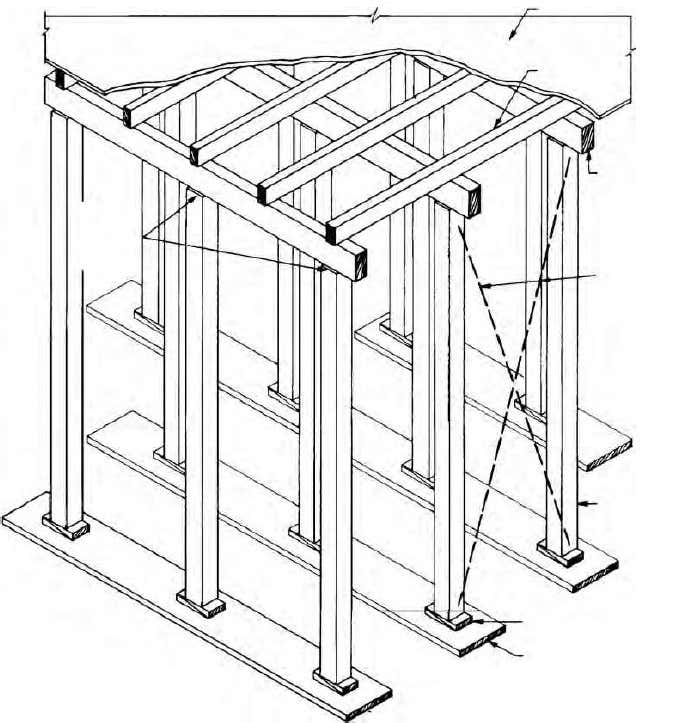

Formwork intro A propping system for a suspended slab "Better ten props too many than one too short" The old guy who said that to me when I was doing my first formwork job meant of course, not only props, but any temporary bracing, struts, tie bolts etc etc36—Inspection and adjustment of formwork 37—Removal of forms and supports 38—Shoring and reshoring of multistory structures backshores—shores placed snugly under a concrete slab suspended) and its supporting structure used for supporting workers, tools, and materials;Our offering includes engineering services, slab installations, formwork, in situ slabs, Echo rib & block slabsGeneral Requirements Formwork shall be so constructed that it will support the loads imposed on it by fresh concrete together with additional stresses imposed by vibrating equipment and by construction traffic For the construction of structural floor slabs formwork shall be used as per shop drawings and manufacturer's recommendations The PD 8 Shoring Tower &

Concrete Slab Wikipedia

Back Propping Idh Design

• Temporary props are equally spaced within each slab span • There are 2 formwork tables for 075mm and 10mm material • Ratio of two adjacent slab spans equal 11, that is I/L=1 • The ratio of the longer slab span (L,) to the shorter slab span (L5) does not exceed 12, that is I 1 / L 5 ≤ 12 2Acrow Props = 8 pieces;2 Formwork design in Section 3 discusses the concept of designing BONDEK as a formwork Section 4 presents the concept of designing BONDEK as a composite floor slab while Section 5 discusses design of composite slab in fire Design tables for steel framed construction are presented in Section 6 Construction and detailing issues are

5 Things To Look For When Inspecting A Suspended Concrete Slab

Skydome Geoplast

A Smartslab suspended concrete floor is noncombustible therefore making it ideal for those building in bush fire prone areas TOTAL SERVICE SMARTSLAB provides a total service for the design and construction of suspended slabs Each slab is individually designed and all our work is installed and certified by an experienced SMARTSLAB teamSuspended slab formwork details Suspended slab formwork detailsThis unit of competency specifies the outcomes required to erect and dismantle formwork to suspended slabs, columns, beams and walls to contain concrete in above ground construction It includes timber, metal or prefabricated formwork of modular or in situ design Application of the Unit Application of the unitThe 6 inch suspended slab in detailShifting trolley is special shifting equipment for table formwork, as we know, in slab construction, we usually divide several construction sections for money saved, that makes turnover of slab formwork be very necessary The speed of moving of table formwork is accelerated by means of shifting trolley, that is why we designed this smart tool 2

Murform Concrete Formwork Contractor Uk Ireland Mitcham S Corner Cambridge Murform Concrete Formwork Contractor Uk Ireland

Formwork Wikipedia

For vertical formwork of columns,vertical face or side face of beam and vertical side of reinforced wall The stripping time period is 16 to 24 hour This time is also know as de suttering periods We remove soffit formwork of slab but immediately fixed props after 3 days(c) Ensuring the work of pouring the concrete slab did not take place until the site's consultant engineer had carried out a site inspection (d) Ensured that an exclusion zone was implemented below the BONDEK formwork during the suspended slab pour 13 Detail the events surrounding the Alleged ContraventionConcrete formworks (shutterings) are required for fresh concrete constructions such as walls, slabs, beams, columns, footings etc Formworks requirements for different structural members are different and they are named based on type of structural member Formwork (shuttering) is a temporary mould to provide support to fresh concrete when placed in structural member until the concrete

Cost Optimization Of A Composite Floor System One Way Waffle Slab And Concrete Slab Formwork Using A Charged System Search Algorithm Sciencedirect

Concrete Slab Abis

Adjustable metal scaffolding can be used for shoring in concrete work, provided its structure has contractor when designing and constructing the formwork Formwork drawingsUsed near the top of the formwork are reused for the bottom of formwork when it is lifted Sky tower in Auckland used a 4m high jump form for the construction of The roof slab will often be larger than the other suspended slabs For the purpose of water harvesting, structural integrity and aesthetics, the roof slab would have projections, that is, it would be extended outwardly This means that even when dealing with formwork, you have to account for that which is placed on the projection soffit

Concrete Slab Wikipedia

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

1 Set the legs Mark out the edge of the set down onto the formwork and align the back of the leg baseplate with this edge then screw rebate legs to the formwork at 1500mm max centre's and adjacent to corners 2 Connect the Rapid Rebate to the support legDetail_080 Concrete filled Rapidwall with RW slab formwork ceiling balcony & set down details Detail_090 Concrete filled Rapidwall with RW slab formwork ceiling internal wall to suspended slab Detail_100 External 45 Degree corner concrete filled or insulated Detail_110 External corner alternative, concrete filled or insulatedThe present invention relates to a formwork arrangement for forming a suspended concrete floor slab comprising a change in level in an underside thereof, a support bracket for use with such a formwork arrangement, and a method for employing the support bracket and formwork

Formwork Construction In Structures

Concrete Formwork For Slabs

Edges of the building footprint The formwork will provide the shape of the slab and hold the concrete while it dries Step 7 Lay polythene sheeting and tape Step 8 Lay steel reinforcement fabric and trench mesh for the slab Step 9 Pour concrete in one operation creating a slab that covers the entire floor area Formwork for a concrete slabSuspended Concrete Slabs and Formwork Systems 11 October 18 According to every engineering handbook, suspended concrete slabs are defined as flat, tablelike surfaces, which have no direct physical connection to the ground Included in the list of challenges faced by a consulting engineer here, there's the formwork system to create, one that'll support and buttress the concrete slabsMarine ply wood = 64 pieces;

Method Statement For Erection And Dismantling Of Slab Formwork Project Management 123

Comflor Non Composite Formwork Composite Floor Deck Tata Steel

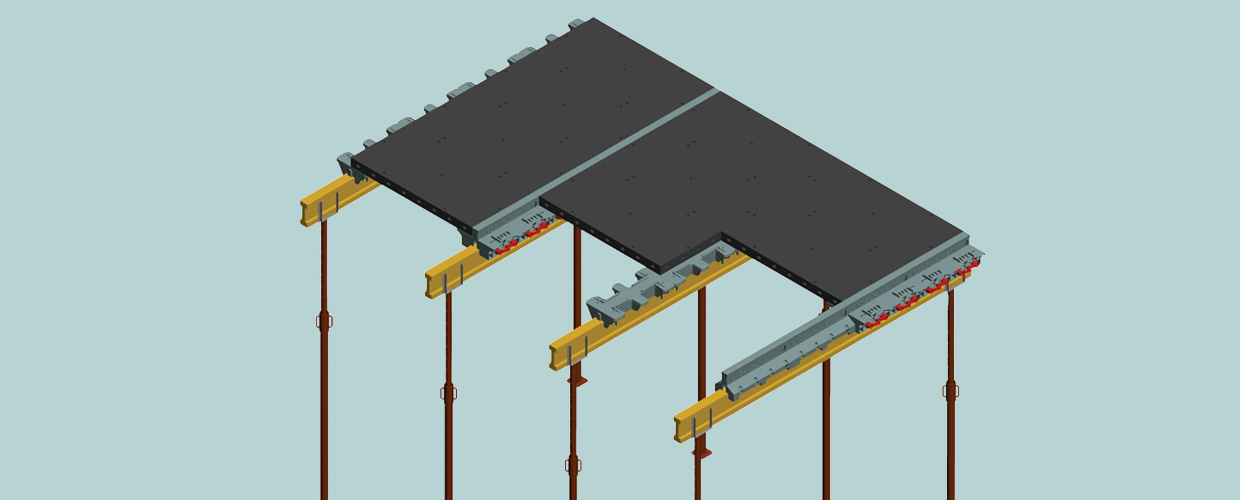

A method of constructing a suspended floor is described in which a plurality of beamforming formwork assemblies are located in substantially parallel alignment, the beamforming formwork assemblies are supported in support assemblies on a support base in stable equilibrium, a plurality of floorforming formwork assemblies are located between the beamforming formworkThe 6 inch suspended slab in detail 21 weighs 75 pounds per square foot but the formwork should be designed to carry psf due to the weight of workers and equipment used during pour That is why concrete formwork for suspended slab has a lot more columns and beams compared to the normal residential floor framingColumn formwork and pouring concrete on site work activities carried out in a factory environment are generally lower risk table or flying forms—a large preassembled formwork and falsework unit often forming a complete bay of suspended floor slab, and modular formwork systems which are often lighter weight and eliminate the need for tasks

Safety Suspended Slab Formwork Shifting Trolley With Hydraulic Power

Commercial Formwork Unitec

The removal of formwork also called as strikeoff or stripping of formwork should be carried out only after the time when concrete has gained sufficient strength, atleast twice the stress to which the concrete may be subjected to when the formworks are removed It is also necessary to ensure the stability of the remaining formwork during formwork removal Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the moulds Formwork can be made using moulds out of steel, wood, aluminium and/or prefabricated forms Formwork is an ancillary construction, used as a mould for a structure Into this mould, fresh concrete is placed flat slab with drop panel and column head Flat Plate A flat plate is a one or twoway system usually supported directly on columns or loadbearing walls Figure It is one of the most common forms of construction of floors in buildings The principal feature of the flat plate floor is a uniform or nearuniform thickness with a flat soffit which requires only simple formwork and is

Slab Formwork Ulma Construction

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

On the right is the slab formwork for a suspended concrete slab to a multi story building, but this system of concrete formwork could just as easily be used on an owner builder house What you see is a series of steel frames with cross braces holding them together They have adjustable screw jacks at the bottom and topCAD/BIM Library of blocks "slab formwork" Free CADBIM Blocks, Models, Symbols and Details Free CAD and BIM blocks library content for AutoCAD, AutoCAD LT, Revit, Inventor, Fusion 360 and other 2D and 3D CAD applications by Autodesk This a type of slab where we find a hollow hole in the slab when the formwork is removed Firstly PVC trays (pods) are placed on shuttering then reinforcement is provided between the pods and steel mesh is provided at top of the pods and then concrete is filled

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

Concrete Formwork For Slabs

What Is The Minimum Number Of Days To Dismantle Formwork In A Reinforced Concrete Slab Quora

Analyzing The Efficacy Of A Suspended Concrete Slab In Formwork And Concrete Construction Asfct Concreting Service

2

Concrete Slab Floors Yourhome

Dam Formwork D22 By Acrownz Issuu

Concrete Slab Floors Yourhome

Large Area Formwork Top 50 By Acrownz Issuu

Week 6 Timber Based Columns Ppt Video Online Download

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Lost Formwork In Flat Slabs

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

1

Slab Formwork Dokadek 30 Doka

Concrete Slab Formwork Flxible Beam Clamp Concrete Formwork Accessories

Structure Suspended Slab Home Building In Vancouver

Truedek Steel Suspended Slab Formwork Systems Australia

Methods Of Installing Floor Slab And Beam Formwork Based On Figure 1 Download Scientific Diagram

4 1 Formwork For Concrete Slab

Back Propping Idh Design

Slab Formwork Systems On Sales Quality Slab Formwork Systems Supplier

Flying Table Formwork For Large Area Slab Concrete Construction

Formwork For Decks And Floors Concrete Construction Magazine

Safety Concrete Formwork For Suspended Slabs China Slab Formwork Aluminum Shutter Made In China Com

Concrete Formwork For Slabs

Structure Suspended Slab Home Building In Vancouver

Formwork

Concrete Formwork For Slabs

Beam Formwork Materials For Concrete Shuttering Wellmade

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Permanent Slab Sofits Expamet

Suspended Floor Flying Table Forms Concrete Slab Shuttering Panel Formwork Buy Kitsen Flying Table Forkwork Forms Suspended Floor Slab Formwork Product On Alibaba Com

Formwork For Decks And Floors Concrete Construction Magazine

Detail Of Reinforced Concrete Slab With Lightweight Concrete Blocks Under Construction Architect Architecture Bar Beam Block Build Builder Building Cement Concrete Concrete Floor Concrete Slab Concreting Construction Construction Site

Concrete Slab Floors Yourhome

Garagedeck The Flexible Formwork Solution For Beam Peri Usa Manualzz

Slab Stopend Construction Joints Expamet

Concrete Formwork For Slabs

Concrete Slab Formwork Buy Concrete Slab Formwork Deck Formwork Steel Props Product On Ngm

Concrete Formwork For Slabs

Suspended Floors All You Need To Know Thermohouse

1

4 1 Formwork For Concrete Slab

Concrete Formwork For Slabs

Construction Suspended Concrete Slab Formwork Systems Shifting Trolley

Provide A Comparison On The Pros And Cons Of The Selected Slab Type Engineering Assignment Help

Raft Slab Formwork

Preventing Concrete Formwork Failures In The Commercial Construction Process

Suspended Concrete Floor Slab Formwork System Pdf

Geosky Geoplast

Things To Check Before Concreting Beams Slabs

Structure Suspended Slab Home Building In Vancouver

5 1 Damp Proofing Concrete Floors Nhbc Standards 21 Nhbc Standards 21

Concrete Floor Slab Construction Process Eplan House

Concrete Slab Floors Yourhome

Variokit Vcb Cantilever Bracket

Structure Suspended Slab Home Building In Vancouver

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

Blog Construction Management Construction Project Management Services And Construction Books

5 1 7 Fill Below Floors Nhbc Standards 21 Nhbc Standards 21

Types Of Formwork Shuttering For Concrete Construction And Application Cement Concrete

Duo System Formwork

Formwork Wikipedia

1

Slab Edge Formwork

Formwork For Beams And Slabs

/concreting-formwork-for-the-foundation-857756224-5b7ed9cdc9e77c00573a1357.jpg)

Safety Installation And Removal Of Formwork

Lift Slab Construction Wikipedia

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

Design And Calculation Of Formwork Requirement Of Slabs Structville

Concrete Formwork For Slabs

Formwork Wikidwelling Fandom

Formwork

Airodek Slab Formwork Products Rmd Kwikform

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Truedek Steel Suspended Slab Formwork Systems Australia

Column Formwork Procedure Formwork For Slabs And Beams

0 件のコメント:

コメントを投稿